Bunkering services

WHAT WE DO

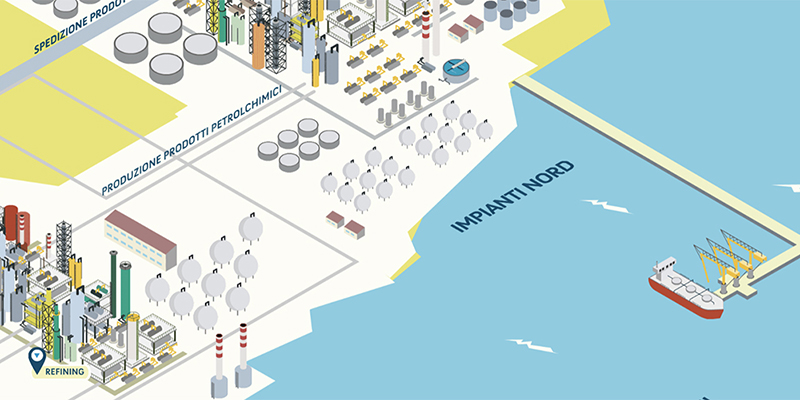

The first sustainable bunkering hub in the Mediterranean operates in dedicated areas of the Sarlux marine terminals and the port of Cagliari.

In addition to the full range of traditional fuels and marine diesel, the Sarlux refinery produces the new ecological fuel oil called VLSFO (Very Low Sulphur Fuel Oil) with very low sulphur content (max 0.5% as per the latest IMO 2020 specifications).

An innovative and modern service that marks a revolution in the bunkering sector globally and that will lead to the production of fuels with near-zero emissions.

The service offered by Saras, marketed by its subsidiary Saras Trading, is designed to meet the needs of ships arriving and departing from the ports of Sarroch and Cagliari and to offer additional supply opportunities, both at the quayside and directly at sea, to the many ships crossing the Sicilian Channel and the Tyrrhenian Sea.

Bunkering is carried out using modern ships, specially designed for this service and equipped with the most advanced safety equipment and trained crews, to guarantee operation in full compliance with environmental, health and safety regulations.