Energy efficiency

ENVIRONMENT

Energy saving and energy efficiency are key priorities and strategic assets for our company as they enable us to couple the goal of environmental sustainability with that of competitiveness.

Our internal energy demand consists of the combustion of petroleum products and the use of electricity and thermal energy (steam).

The commitment to improve the site’s energy efficiency started back in the late 1970s and early 1980s, with major investments in the recovery of heat and energy.

Over the years, we have implemented major heat recovery projects. Together with operational improvements, these projects have enabled us to reduce steadily energy consumption, thus contributing to the protection of natural resources and the ecosystem.

Another step to improve our energy performance is to have a full picture of our facility’s energy consumption, so as to better identify potential areas for improvement in the short, medium and long period.

To do this, we developed the Energy Management Dashboard, an energy consumption monitoring system that uses actual data, processes it according to type of plant and energy carrier, and produced comprehensive and detailed energy analyses.

Another indication of our commitment on this front is our decision to adopt an Energy Management System (SGE), (EMS), under UNI EN ISO 50001:2018, to improve our energy performance by reducing energy consumption, emissions and costs, and by improving the efficiency of our energy-intensive production processes.

THE ENERGY EFFICIENCY OF THE SARLUX INTEGRATED CYCLE

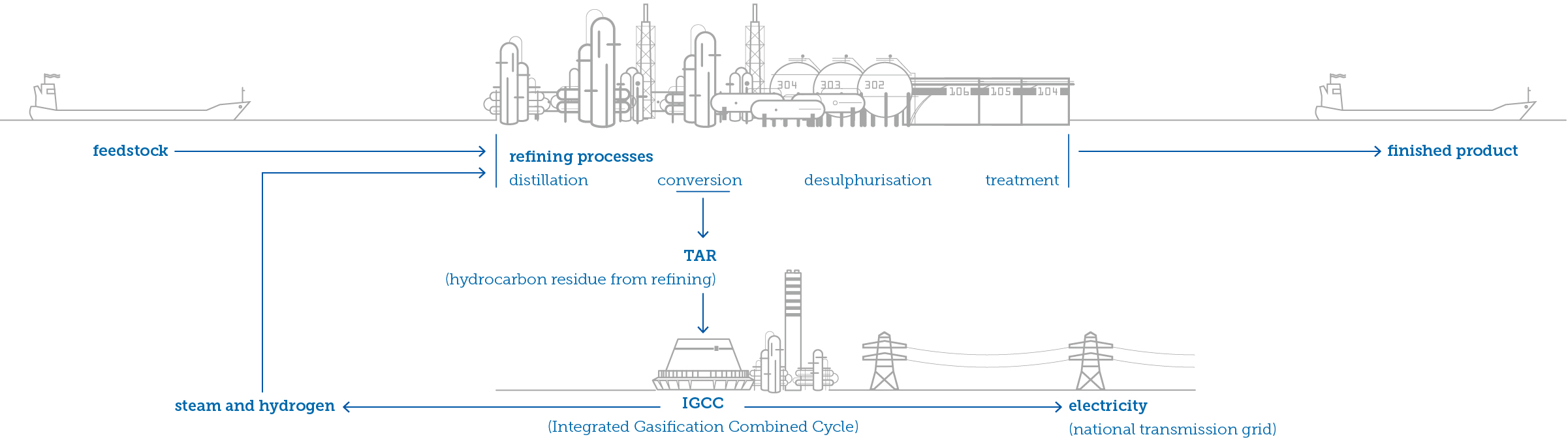

Taken as a whole, the South plants, the IGCC plant and the North plants form a single integrated cycle that transforms hydrocarbon inputs into refined petroleum products, petrochemical products and energy.

The energy efficiency of the integrated cycle is the ratio of energy input to energy output as the sum of the energy content of the oil products and energy sold.

The difference between energy inputs and outputs is mainly due to the internal consumption of energy absorbed by production processes and to energy use by ancillary activities.

THE ENERGY EFFICIENCY OF THE IGCC PLANT

The Sarlux Integrated Gasification Combined Cycle IGCC (Integrated Gasification Combined Cycle) plant generates electricity for resale and hydrogen and steam for use in the refining cycle from heavy hydrocarbons (tar), a refinery product that would otherwise be used to produce fuel oil.

The tar is gasified, i.e. purified and transformed into syngas, a clean synthesis gas similar to methane.

The syngas is used to power the turbines and produce electrical energy.

The IGCC is a combined cycle cogeneration plant, which generates at the same time electricity to be fed into the grid and hydrogen and steam to power the refinery’s plants.

The energy efficiency of the IGCC plant is given by the ratio of the energy input into the IGCC – in the form of hydrocarbon feedstock and electricity consumed – to the energy output in the form of electrical energy, steam, hydrogen and sulphur.

The IGCC plant’s energy efficiency is far higher than the level achievable by traditional thermoelectric power plants.

Source: Saras Corporate Sustainability Report 2023