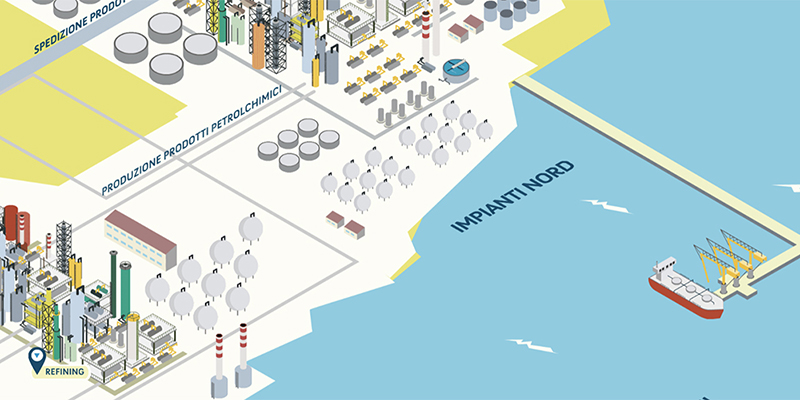

Energy production

WHAT WE DO

A highly integrated and efficient process. The Integrated Gasification Combined Cycle (IGCC) plant generates electricity, hydrogen and steam from the heavy hydrocarbons which are a by-product of the refining process (tar, a substance similar to bitumen).

HIGH ENVIRONMENTAL QUALITY

The IGCC plant’s technology is one of the best currently available to generate electricity and, certainly, the cleanest among those powered by liquid hydrocarbons.

It is recognised by the European Union as Best Available Technique to limit the environmental impact of refineries as it minimises emissions into the atmosphere and noise impact.

The Environmental Impact Assessment certifies that the integration of the power plant with the refinery reduces the overall impact of the industrial site in terms of air emissions.

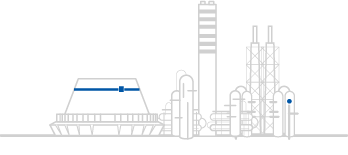

THE IGCC PROCESS

The IGCC plant is a highly integrated and efficient process which, in addition to generating electricity, produces hydrogen and steam for refining plants, in cogeneration mode.

The first step takes place in the gasification section, where the semi-finished product coming from the refinery’s Visbreaker plant (tar or feedstock) is transformed, using oxygen, into synthesis gas (syngas).

The syngas is cleaned of the sulphur and metals it contains in the scrubber, thus becoming a clean gas, similar to methane, which is then burned in the gas turbine that produces electricity and hot gas.

The hot gas, together with the water from the seawater desalinator, produces the steam that powers the steam turbine, which in turn produces electricity.

The metals that are removed from the syngas during the gasification process are compacted and recovered as a coal-like substance, called ‘filter cake’, which contains high percentages of precious metals such as vanadium and nickel. The filter cake is sent to Germany, where the metals are recovered for use in a number of sectors: in the metalworking and pharmaceutical industry, for the production of paints, etc.

The sulphur recovered from the syngas production process has various uses: in the chemical sector (hydrogen sulphide for batteries), in agriculture (fertilisers and insecticides) and in the pharma industry.

Although the process is very complex, the IGCC plant has achieved excellent production results since its first year of operation.

THE HISTORY OF THE IGCC PLANT

This is the most important private industrial initiative in Sardinia in the last 20 years.

In 1991, under the new National Energy Plan, in order to deal with the growing demand for electricity in our country, which at the time was mainly met by fossil fuel-fired plants with high emission levels, the Italian Government asked some independent power producers to construct power plants using renewable or equivalent sources.

This led Saras to launch its project for an IGCC (Integrated Gasification Combined Cycle) power plant, to produce electricity by gasifying the hydrocarbons left over from the oil refining process. This innovative process ensures that the IGCC plant is fired by a clean gas, with an environmental performance similar to methane gas.

In 1996, the project was financed by a combination of bank financing and shareholders’ capital contributions. Construction began in 1997, by an international joint venture composed of Snamprogetti, General Electric and Nuovo Pignone. The plant, which has installed capacity of over 575 megawatt (MW) and generates over 4 billion kilowatt-hours (kWh) of electricity per year, went live in December 1999.