In the heart of the industrial area with Sarlux contractors’ workers

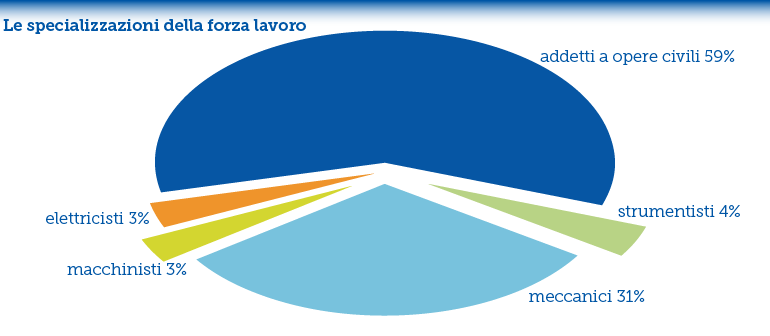

Carpenters, scaffolders, masons, sand blasters and workers engaged in efficiency and safety checks at the Sarlux industrial site of Sarroch. In total, over 1,000 technical workers, employed by about 57 companies, were involved in the shutdown maintenance works which were completed in March. Over a period of two months, the workforces of Sarroch and, in general, of the province of Cagliari, carried out more than 580 operations. Some were quite complex, and served to improve the efficiency of the Saras Group plants, especially in terms of environmental performance. The whole maintenance project was completed within the planned timeframe, and ensuring the highest safety standards. Workers’ data show the profiles in highest demand: civil construction workers (59 %) and mechanical technicians (31 %). Next came equipment operators (4 %), electricians (3 %) and machinery operators (3 %).

The pie chart shows the breakdown by profile of the specialists contracted by Sarlux during the maintenance works of February and March 2016. Most of the technicians are local

Expert workers replaced exchangers, checked dozens of valves, monitored instrument performance, while the equipment was halted for scheduled maintenance. They checked the equipment and machinery’s “health status” and performed the appropriate maintenance-upgrading works as per the plan, ensuring ongoing control of the efficient operation of the site’s various areas. Divided into teams, constantly coordinated by Sarlux staff, the workers installed scaffolding, welded metal parts, performed blast cleaning and adjusted valves, often operating in difficult conditions, for instance in confined spaces.

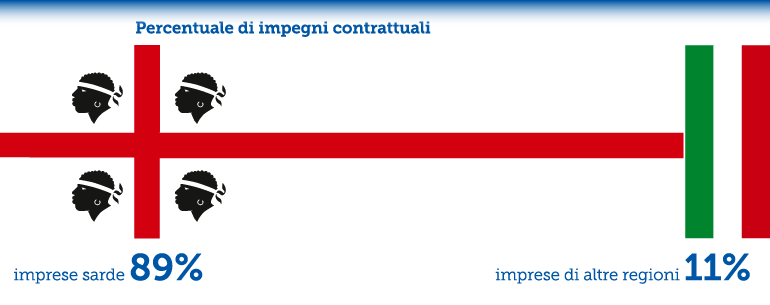

These works were all performed by specialist technicians who have built their expertise in the firms servicing the Sarroch industrial area. Most of these technicians live in the province of Cagliari: about 90 % of the budget for this maintenance project went to local firms.

Most maintenance works are contracted to local firms

Work and Safety

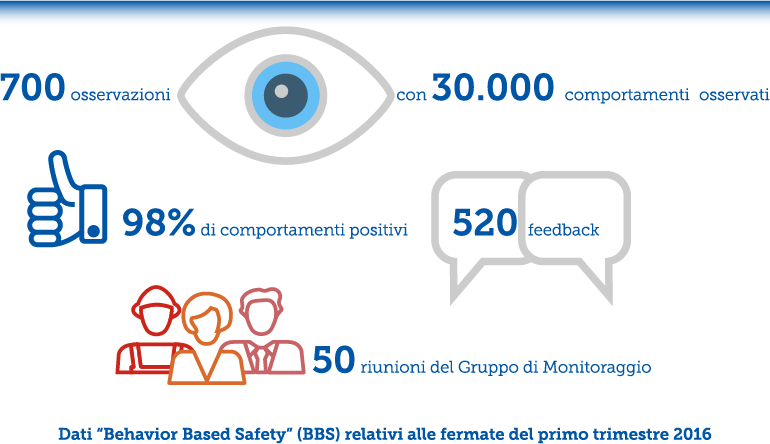

An essential element in any activity, be it civil works or sophisticated intervention on plant sections, is staff training and detailed briefings to contractors’ staff on the stringent safety procedures. Sarlux complies fully with all legal requirements, which include a series of procedures covering the entire day the plant is halted or even the full 24 hours. In addition to regulatory compliance, the company has also introduced other functions and checks, such as the “safety licence”, on-the-spot verification and observation of direct and indirect staff behaviour according to the BBS “Behavior Based Safety” principle. This method is based on visual assessment of the way in which workers behave or act, including in the simplest and most routine actions. If the observation reveals errors or actions that might lead to unsafe behaviours, the worker receives a warning intended to correct the bad practice, in order to prevent any accident from occurring. During the maintenance shutdowns, inspections, checks, information meetings and many other activities are stepped up, in a tight sequence that closely monitors site activities. With regard to checks, during this maintenance session, on-site checks recorded 30,000 workers’ activities, in the course of 700 observations, resulting in 520 feedbacks. The result was very satisfactory: 98% of the observations had a positive outcome. The monitoring group met at least 50 times, in practice every working day during the shutdown period.

A typical maintenance shutdown day, with site checks and coordination briefings

A safe site is a place where all the operators share the appropriate information: awareness of what happens around them is paramount for maintenance workers. Thus, the first aim is to remove any interference between different tasks, i.e. any activity by a work team that might disrupt the work of colleagues at an adjoining site. The keywords are coordination and information. The maintenance work is planned by external experts (as required by law) including the coordinator of design safety and the coordinator of execution safety, two roles at times held by the same person. This figure, like the conductor of a large orchestra, oversees maintenance project in close coordination with Sarlux’ Maintenance, Operations, Safety prevention and protection departments.

7 am: from the briefing to the cross-checks on the IT system

The day starts early, with the briefing 7.00 briefing between maintenance staff and the contractors’ representatives. Next, at 8.00 am, the safety coordinator turns on the IT system that provides a complete overview of all the scheduled maintenance activities: the IT system managing the work permits also allows checking of the details on the day’s planned activities. Then the work day can start: the workers go to their workstations, followed by the inspectors.

8.30 am: the on-site checks begin

Control of site activities is an integral part of maintenance shutdowns. Checks and inspections are carried out by a number of parties, using different methods. The aims are many. In general, inspectors check the workers’ mastery of the individual tasks assigned to them. They may also check the workers’ awareness of the safety equipment present at the site. The results of the inspections highlight any need for additional training or information to workers, which is then delivered promptly by Sarlux.

10.00 am: first coordination meeting

The safety coordinator meets the representatives of the contractors together with the Sarlux officers from the Prevention and Protection Department (PDD), Maintenance and Operations to plan the maintenance activities at the various units that have been shut down. The aim is to allow all workers to perform their tasks without any interference from nearby workers/sites. The contract workers’ cooperation is essential.

1.00 pm: assessment of inspections

During the morning, several meetings were held between Sarlux officers from the relevant departments and the contractors. Meanwhile, the inspectors went on site to check that all activities were conducted in compliance with safety standards. Around 1.00 pm, the safety coordinator can convene his team to make the daily assessment of the workers’ safety compliance and plan any improvement actions. This assessment is the basis for planning any targeted training.

4.00 pm: second meeting with the contractors

The evening meeting is a sort of preview of the next morning’s meeting: the safety coordinator receives preliminary information on the next day’s activities, in order to plan the work to be developed and fine-tuned the following day.

5.00-7.00 pm: more on-site checks

Throughout the evening, the officers checking compliance with rules and safe practices inspect the site areas involved in the shutdowns. These onsite inspections crucially ensure communication between safety planners, safety plan coordinators, the contractors’ workers, who can work at the site only if they hold the “safety licence” and the Sarlux personnel, who oversee all maintenance operations. In some cases, maintenance does not stop even after 7.00 pm: some activities may continue through the night.